Detection of material defects by means of acoustic emission

| Please contact us at: |

|---|

| +49 (0)234 / 587 - 6000 |

| zfp@akuvib.de |

| Submit request |

By means of acoustic emission, even insidious changes in the material can be located

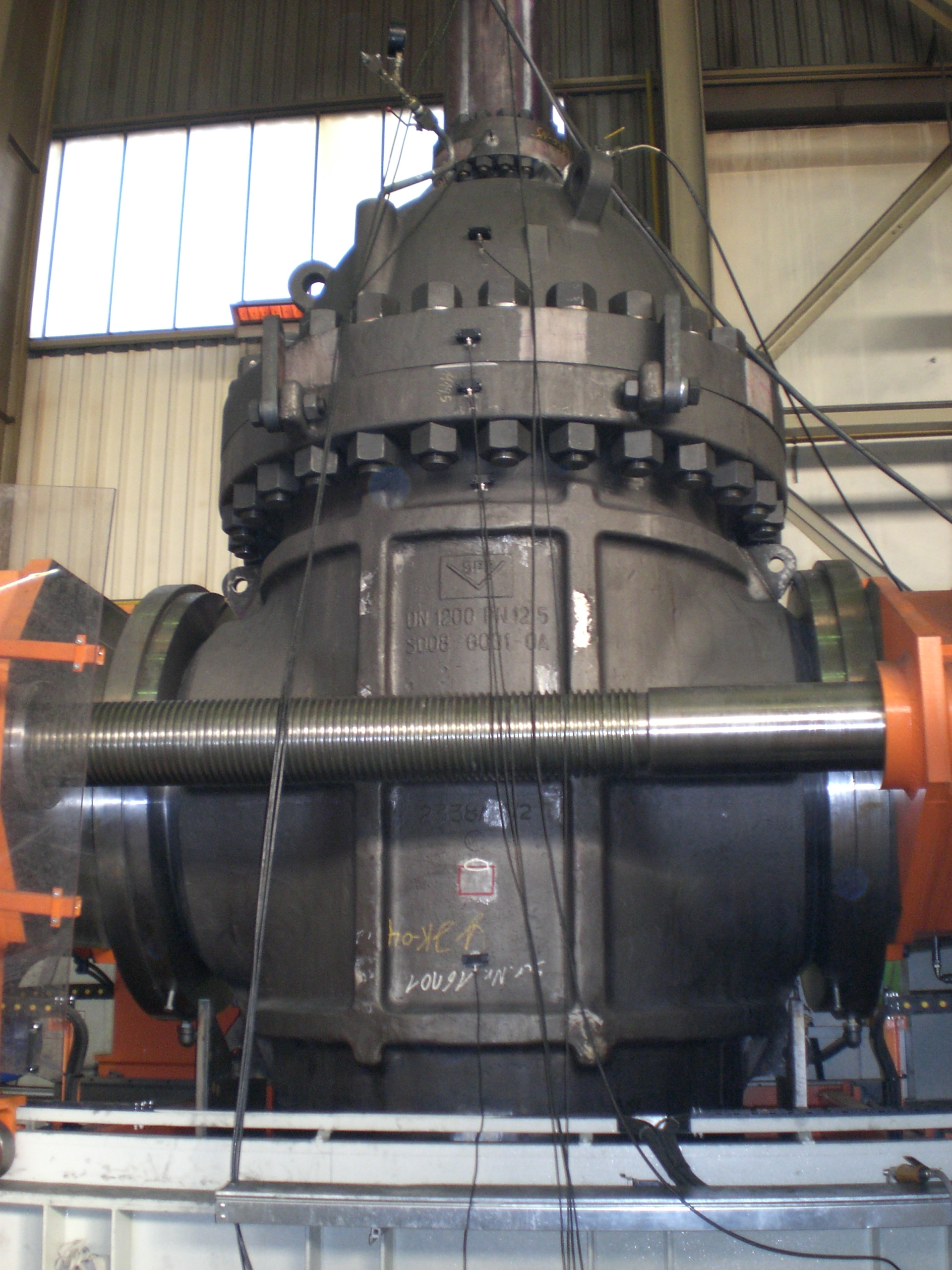

The acoustic emission is used to determine defects in the structure, to detect rust or to detect internal leaks, for example in valves. Acoustic emission (AE) works in a frequency range in which classical structure-borne sound analysis reaches its limits and is also increasingly applied in machine diagnosis.

A change in the structure, the growth of rust, the formation of cracks or the rubbing together of materials triggers a surface wave in the material, which is recorded with the acoustic emission measuring system.

By selecting the appropriate acoustic emission sensors and their number, AKUVIB is able to precisely localise the defect.

The display of the events in real time enables online monitoring during pressure tests. Flaws in the material trigger acoustic emission waves that are detected by the system. The advantage over conventional non-destructive testing methods is that the test objects, e.g. tank systems, can be tested in a filled state or under pressure.

In this way, downtimes can be shortened and emptying can be avoided. Furthermore, it is possible to distinguish between active and passive defects in the structure. Suitable measures can thus be initiated on site.

Examples of areas of application are:

- Testing of tank installations or tank bottoms

- Examination for internal leakage of valves

- Crack and defect localisation during pressure tests

- Inspection of pressure vessels and boilers

- Monitoring of slowly rotating bearings

- Stick-slip behaviour of material pairings

Our possibilities:

- Stick-slip examinations

- Localisation of crack and rust growth during operation

- Detection of delamination faults

- Bearing monitoring

- Inspection of tank bottoms

- Online monitoring for permanent surveillance

- Detection of faulty spots, material defects or deviations in the structure

- Detection of leakages at valves

- Mobile measuring equipment